-

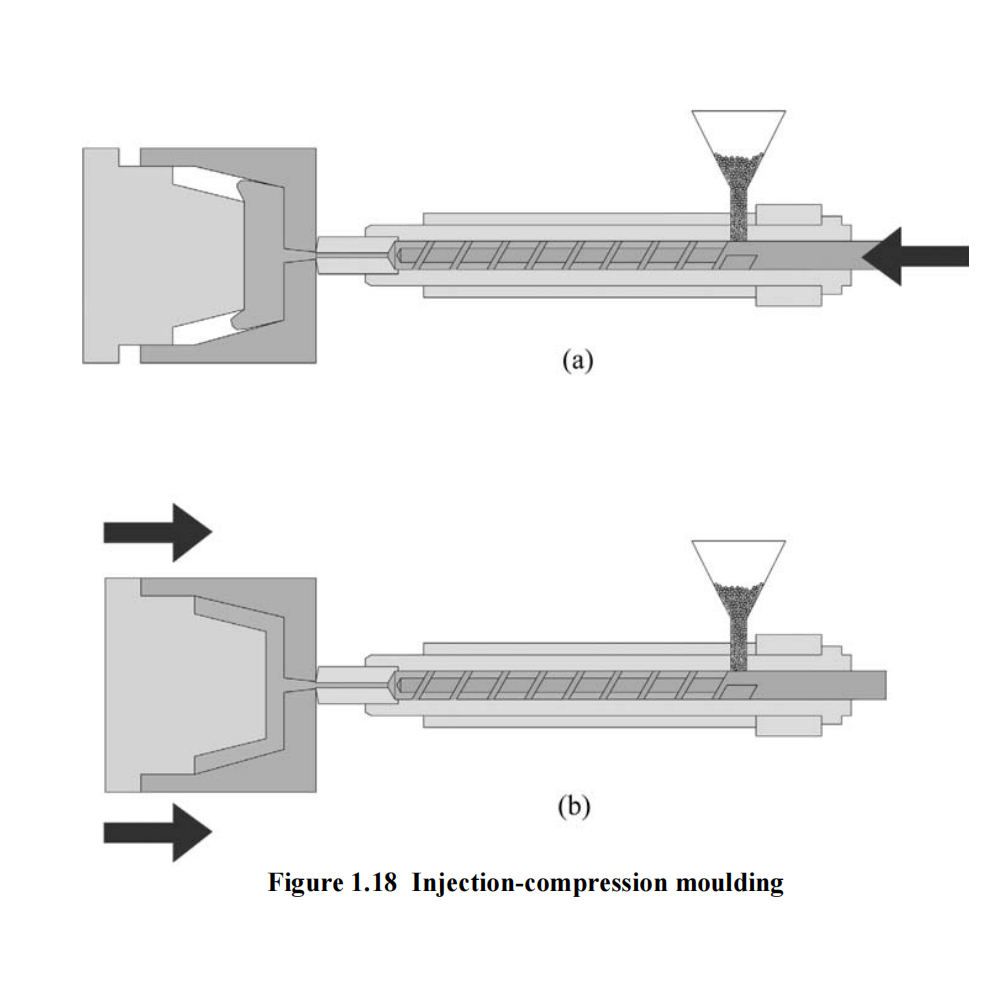

Injection-Compression Moulding

The injection-compression moulding process combines elements of both the injection moulding process and the compression moulding process.

Compared with injection moulding, there is a big reduction in the filling...

Date : 09/19/2022 | View : 3492

-

Packing and Solidification

Once the material is in the tool, filling must be completed (tool packing), the part cooled and finally ejected. The purpose of the packing stage is to add extra material to compensate for the shrinkage caused by the...

Date : 09/13/2022 | View : 3425

-

Blow Moulding

Blow moulding is the third most commercially important process for plastics production after extrusion and injection moulding. It is used to produce a range of hollow articles for example bottles, fuel tanks and other...

Date : 09/01/2022 | View : 3493

-

Elastomer Injection Moulding Compounds

This section will discuss issues relating to the injection moulding of rubbers, specifically to the

moulding of liquid silicone rubber (LSR) which is of large commercial interest. Firstly however, a quick

introduction to...

Date : 08/31/2022 | View : 3029

-

Reciprocating Screw Machine

For a reciprocating screw machine the process cycle can be split into five stages:

1. In stage one, as shown in Figure 1.6, material is injected into the tool.

2. In stage 2 (Figure 1.7), the screw begins to...

Date : 08/29/2022 | View : 3534

-

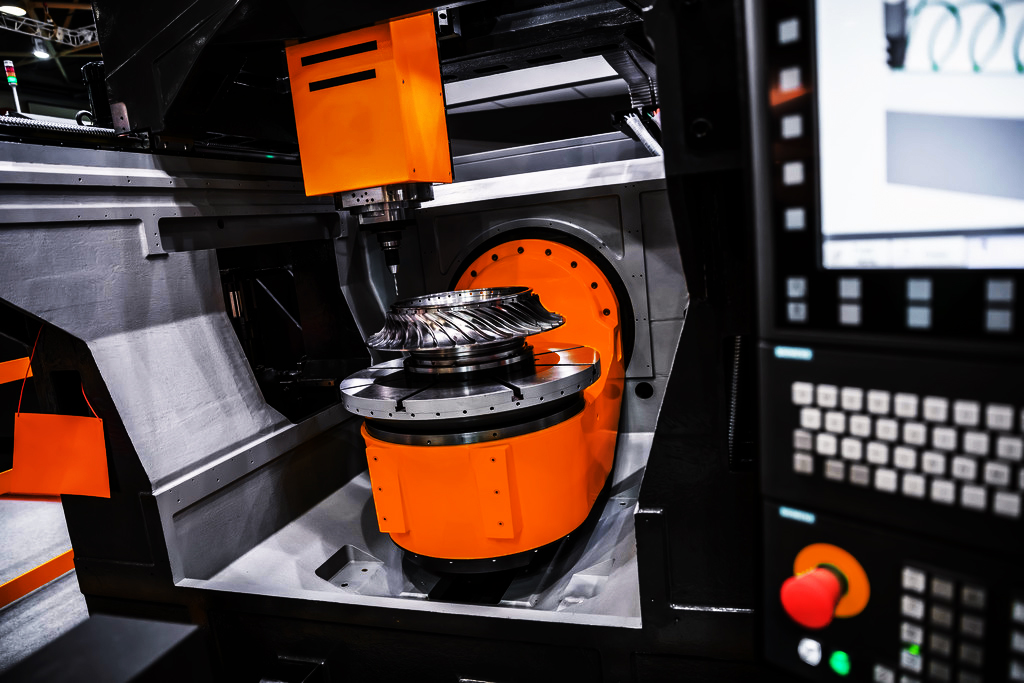

Breaking Down the Injection Moulding Cycle

A single injection moulding cycle can be broken down into three distinct stages: plastication, mould filling and cooling with solidification.

1.3.3.1 Plastication

This stage is carried out in the injection...

Date : 08/20/2022 | View : 3284

-

Burnt Streaks (Brown or Silver)

Physical cause

Burnt streaks are caused by thermal damage to the melt. The result can be a decrease of the length of the molecule chain (silvery discoloration) or a change of the macromolecules (brownish...

Date : 08/19/2022 | View : 2973

-

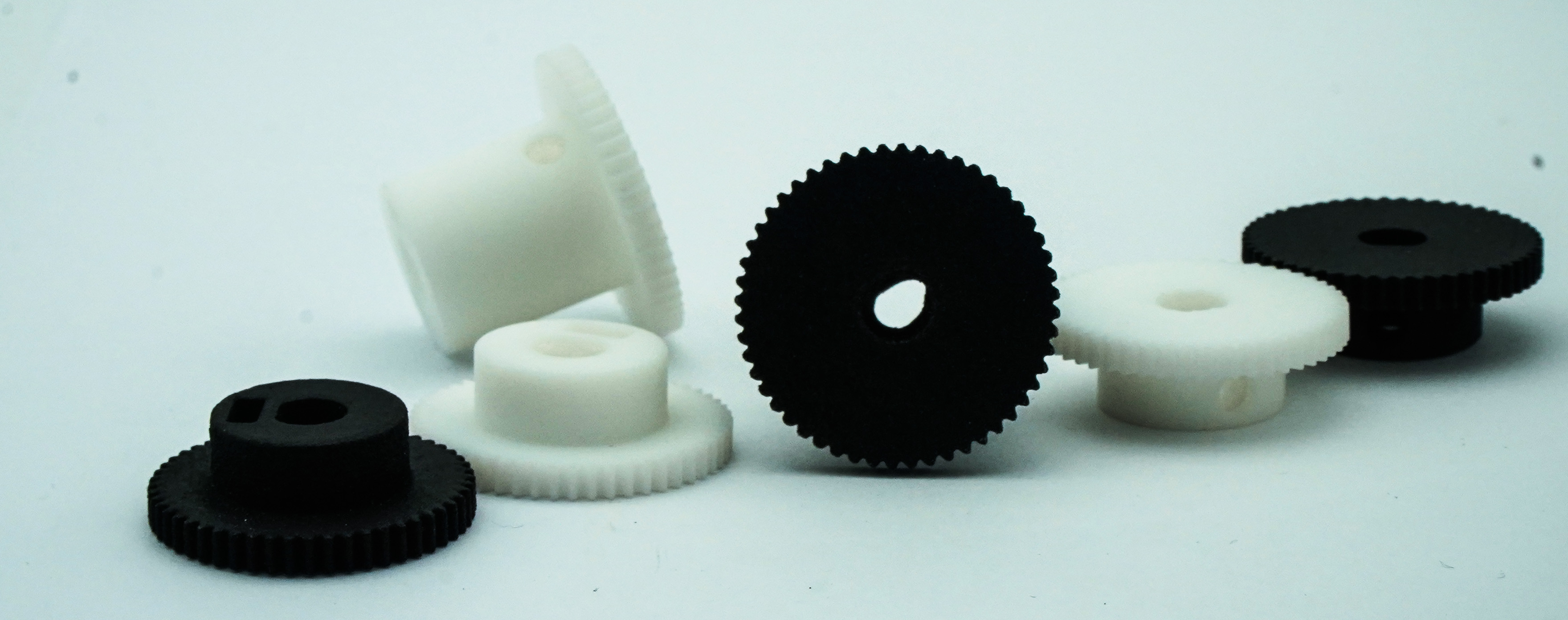

Polyacetals (POM)

Homopolymers or copolymers made from formaldehyde.

Typical Characteristics and Applications

• High levels of hardness and rigidity

• Good elastic properties

• Low creep tendency

• Good...

Date : 08/17/2022 | View : 3350

-

Processing Amorphous and Semi-Crystalline Thermoplastics

6.1 Introduction

Thermoplastics can be subdivided into two distinct classes based upon differences in molecular structure. These differences can have a bearing on the performance of mouldings in service, and have...

Date : 08/09/2022 | View : 3354

-

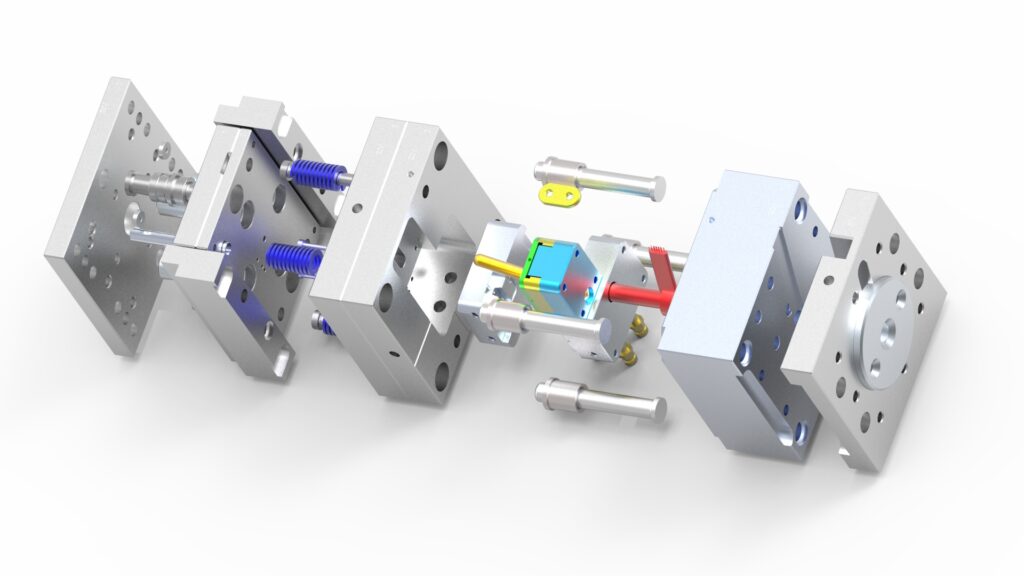

Injection Mould Tooling Basics(2)

4.1.2 Stripper Mould

A stripper mould is very similar to the standard two-plate mould except for the ejection system. This design has a stripper plate for ejection, whereas the standard one has pins or sleeve as...

Date : 08/05/2022 | View : 3351

Displaying 1 to 10 (of 129 Information)

.png)